Part Leveling Machines

Flattening and de-stressing Sheet Metal: Optimum leveling results and excellent efficiency

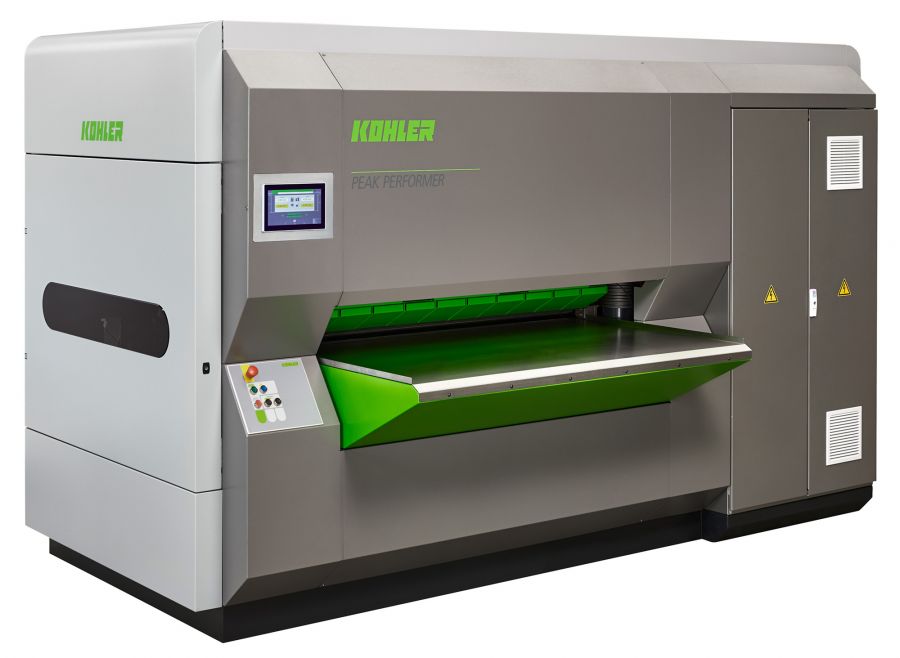

The Peak Performer part leveling machine from KOHLER reliably and precisely levels and relieves stress from sheets and part blanks. Your downstream production processes benefit from higher quality leveled parts and sheets, as there's no need for time-consuming, manual rework.

Product highlights:

- Servo-electronic machine concept without hydraulics

- Electromechanical dynamic leveling gap control (patented)

- Advanced cleaning system

- Reversible leveling rollers (patented)

- Innovative control system

- Predictive maintenance

KOHLER's part leveling machines have no hydraulic systems whatsoever, which means that coupled with their excellent energy efficiency, they play an active role in saving resources in industrial sheet metal processing. KOHLER is breaking new ground and confirming its position as the market leader with its use of direct drives and electromechanical dynamic leveling gap control in hydraulic-free part leveling machines.

The KOHLER Peak Performer part leveling machines level sheets that are 0.2 to 66 mm thick.

Quality-focused industrial companies from a wide range of industries, such as those listed below, rely on part leveling machines from KOHLER.

- Automotive engineering

- Construction and agricultural machinery

- Mechanical engineering

- Steel service centers

- Housing construction

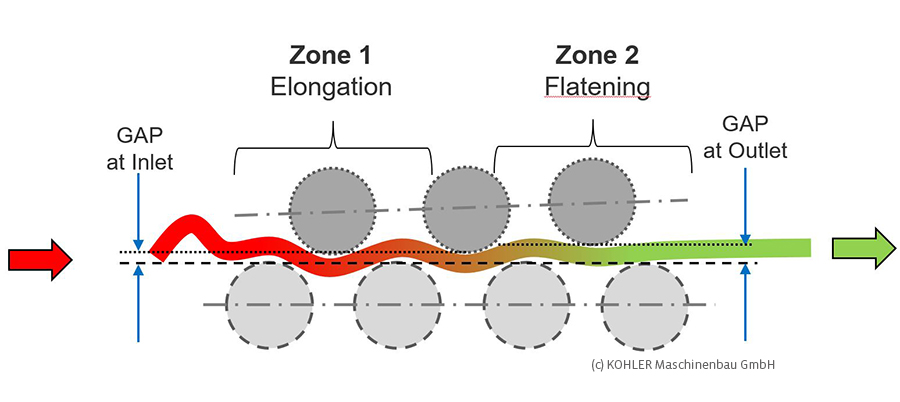

The importance of part leveling in metal fabrication

Flat parts can boost bending and welding productivity and keep customers happy

The sheet metal and plate that gets delivered to a metal fabricating company looks flat enough. But looks can be deceiving, and that is especially true with metal. What might seem flat at first is likely to lose its flatness during fabricating. This makes sense when you consider what happens to the raw material before it’s delivered to the shop. Sheets and plates come from the mills in coils. In metal service centers, these coils are uncoiled, straightened, and finally cut to length. Although the sheets appear to be flat, they still have stress inside. (The stress is evident in the material’s grain.)

What are metal fabricators to do to combat the stresses introduced during coiling and released after the parts have been cut or punched? This is where a part leveling machine can help. What are metal fabricators to do to combat the stresses introduced during coiling and released after the parts have been cut or punched? This is where a part leveling machine can help.

The Fabricator has published the fantastic article on "The Importance of Part Leveling in Metal Fabrication". Click on the link below to learn more.

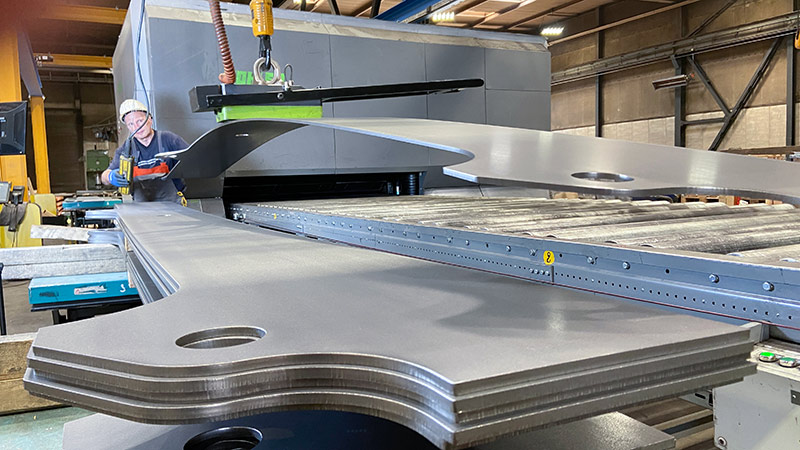

Parts leveling on a KOHLER Peak Performer

Precise, efficient and cost-effective.

Whether with your own parts leveler from KOHLER or leveled on a contract basis at KOHLER: In many cases, this already pays off in the next production step such as bending, welding or assembly. Many different state-of-the-art Peak Performer part levelers are available in the KOHLER leveling center.

Perfectly leveled and deburred

One line, optimal results, seamless processing

Integrating a leveling machine and a deburring machine into a single production line offers numerous advantages. By combining both processes seamlessly, time, space, and energy are saved as parts are efficiently processed in a single pass. Simultaneous leveling and deburring ensure consistent quality and reduce the need for subsequent rework. This optimizes the entire production process, lowers costs, and increases productivity. Additionally, placing both machines in a single line allows for simplified control by just one operator, further streamlining operations.

Part leveling machine in steel processing

For level, low-tension blanks, sheet metal specialist DEUMU depends on the precise and efficient Peak Performer part leveling machine from KOHLER.

The Peak Performer 130P.2000 impresses with forward-looking features and guarantees optimum leveling results as well as flexibility, reliability and low operating costs. One of the decisive factors here is the ultra-modern servo-electronic machine concept and the complete absence of any hydraulics. This fact was one of the reasons why DEUMU opted for a KOHLER Peak Performer.

Part Leveling Machines for Light Laser and Stamped Parts

Typical applications: laser job shop, equipment manufacturing, electronics industry, aviation, automotive, precious metal processors, and custom applications

Precision leveling of small and medium-size parts. Excellent leveling results are achieved through the use of small leveling roller diameters, optimum roller spacing, and extra-wide supporting rollers.

The Lucy Group, a leading provider of products for power distribution, relies on KOHLER part leveling machines type 45P.900 to optimize the production of high-quality control cabinets. By leveling laser-cut sheets, internal stresses are reduced, which significantly improves efficiency and quality during subsequent welding and assembly. This technology ensures the precision of the final product while simultaneously reducing rework and scrap.

Part Leveling Machines for Laser, Plasma, and Stamped Parts

Typically used in laser job shops, steel building, mechanical and plant engineering, and general sheet metal production

Versatile machine for sheets up to 16 mm thick. It precisely and reliably levels all conventional materials thanks to its patented dynamic leveling gap control. The servo electronic machine concept operates entirely without hydraulics. The leveling rollers and supporting rollers are quick and easy to clean with the advanced cleaning system developed by KOHLER. The machine offers further benefits such as reversible leveling rollers, pinch point prevention, extra-wide supporting rollers, and intelligent return feed operation.

The Mueller Group, a leading manufacturer of tanks for the dairy and brewing industries, uses the KOHLER Peak Performer part leveling machine 60P.2000 to optimize its production. The machine eliminates unevenness in sheet metal parts with high precision, which significantly improves the subsequent welding and assembly processes and increases the quality of the end products.

Part Leveling Machines for Medium-Sized and Heavy Blanks and Sheets

Typically used in laser job shops, flame cutting shops, heavy-duty mechanical and plant engineering, the railroad industry, and shipbuilding

For use with materials up to 65 mm thick. The servo electronic machine concept impresses with powerful, energy-efficient direct drives. The machine offers high performance yet low operating and maintenance costs. Like all KOHLER part leveling machines, no hydraulics are used. The patented dynamic leveling gap control ensures reliable, precise leveling of all conventional materials. Leveling rollers and supporting rollers can be cleaned quickly and efficiently, thanks to the advanced cleaning system. Other benefits include reversible leveling rollers, pinch point prevention, extra-wide supporting rollers, and intelligent return feed operation.

EKO MEĐIMURJE, a leading European metal processing company, uses the KOHLER Peak Performer 85P.2000 part leveling machine. With this system, the company manufactures high-precision sheet metal constructions, such as driver cabins for mobile work machines and ovens, by reducing distortion during welding and ensuring long-term product quality.

Part Leveling Machines with Roller Bending for Targeted Elimination of Edge or Center Waves

Typically used for perforated sheets and panels

This machine type is ideal for eliminating edge and center waves by pre-bending the leveling rollers using a wedge system which can individually or collectively adjust the lower supporting roller blocks. The varying lifting and lowering results in controlled pre-bending of the leveling rollers. The modern machine concept also works without any hydraulics – like all KOHLER part leveling machines.

Read our report "The challenge of perforated sheets": Perforated sheets are very different to unperforated sheets. It's the holes that cause particular stress and unevenness during the manufacturing process. These negative effects must be fully eliminated so that the sheets can undergo subsequent processing steps. This poses a huge challenge for manufacturers of perforated sheets, but one that can be mastered with the right leveling technology and an experienced helping hand.

Tandem Leveling Line – The Perfect Combination for Round Parts

Typically used for all round parts with stringent levelness requirements

The tandem leveling line levels round parts in a single pass in both directions, offering excellent productivity and leveling results in terms of levelness and concentricity.

The line combines two part leveling machines with a turning station in between.