New Part Leveling Machine: Peak Performer 90P

Energy-Efficient, Cost-Optimized, Easy to Maintain

The new Peak Performer 90P from KOHLER sets new standards in industrial sheet metal processing. Featuring a servo-electronic drive concept without hydraulics, patented electromechanical dynamic leveling gap control, and reversible leveling rollers, it delivers first-class leveling results – with up to 75% less energy consumption than conventional hydraulic leveling machines on the market.

Whether for cutting, punching, or welding, low-stress, flat sheets ensure perfect further processing. The 90P handles sheet thicknesses from 1 mm to 28 mm and throughput widths up to 2,500 mm – all efficiently, compactly, and resource-friendly.

Advantages at a Glance:

- Hydraulics-free & energy-saving

- Reduced maintenance through fewer spare and wear parts

- Functional, compact design saves space & transport costs

- Intuitive operation with Expert-Calculation-System

- Intelligent lighting for enhanced process reliability

Low-tension strips for stable production processes

KOHLER has developed a compact precision leveling machine that has been specially designed to meet the requirements of manufacturing plugs, connectors, and electronic components.

- Improved compliance with the required tolerances

- Material deviations during a coil change pose no problem due to indexed, uniform tension progression

- Reduced twisting and warping of the stamped strip material to be wound

- Greater degree of plastification possible

KOHLER Peak Performer Part Leveling Machine

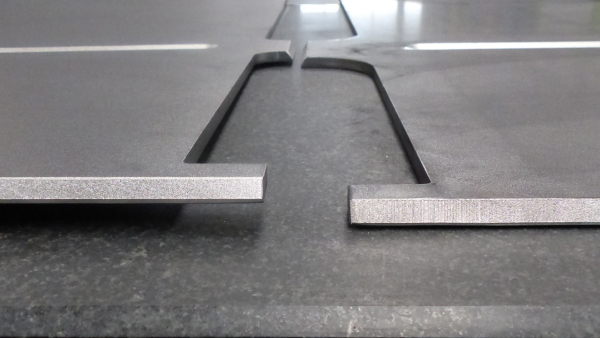

Precise leveling guarantees low-tension and level sheets and part blanks

The Peak Performer part leveling machine from KOHLER comes with a range of forward-looking technical features such as:

- Direct drive for the leveling rollers for greater energy efficiency, less wear and a greater machinable profile

- Advanced cleaning system for easy cleaning of the leveling rollers and supporting rollers

- Electromechanical dynamic leveling gap control (patented) for a reliably constant gap

- Reversible leveling rollers (patented) for a longer service life

- Extra-wide supporting rollers for extremely stable support for the leveling rollers

Each Peak Performer operates without hydraulic systems and so combines ultimate precision with maximum efficiency as well as environmental sustainability. Reduced energy consumption, lower maintenance requirements, zero leaks, and no susceptibility to temperature fluctuations reduce costs and maximize efficiency.

When It Comes to Flexibility and Economy in Production

Leading industrial companies choose KOHLER strip feeding lines for their leveling tasks

KOHLER develops and produces strip feeding lines for presses and automatic stamping machines, as well as cut-to-length lines, for steel service centers, mechanical engineering firms, and for the automotive industry. Strip feeding lines from KOHLER level sheets with outstanding precision. While developing our newest generation of strip feeding lines we focused on economics and efficiency:

- Modern drive concept for the leveling rollers

Direct drives without cardan shafts reduce the maintenance efforts and increase energetic efficiency - Compact design:

The new strip leveling machine requires 20% less floor space

Precision strip leveling machines with direct drives can be delivered with up to 21 leveling rollers. The diameter can range between 40 and 65 mm depending on the application. Systems with conventional drive can also be delivered with leveling rollers in diameter range 18-30 mm.

Strip feeding lines from KOHLER level sheets with high precision. They are characterized by

- high serviceability

- economics and

- longevity.

The portfolio covers the following components:

- Coil handling

- Coilers

- Levelers

- Roller feeders

- Shears

Contract Leveling at the KOHLER Leveling Center

Economical and precise leveling without owning a leveler

Very small batches for leveling? Fluctuating order levels? If it doesn't make economic sense to invest in your own part leveling machine, let our expert personnel carry out your leveling tasks on our state-of-the-art Peak Performer part leveling machines at our leveling center in Lahr, Germany. Depending on requirements, we can handle your entire task – including transport – or provide helpful advice if you want to carry out leveling on our machines yourself. Our strengths include comprehensive, individual advice and the ability to process your tasks as quickly as possible so you can supply your customers on time.

Why choose KOHLER for Leveling?

KOHLER is a pioneer and leader in innovative leveling technology

We set standards in the field of leveling technology through our expertise and innovative solutions, such as trendsetting drive concepts and hydraulic-free part leveling machines. Our headquarters and production facility are located in Lahr in southern Germany, with a further site in Shanghai, China. With a history stretching back over more than 60 years, KOHLER has successfully completed more than 6,700 reference projects around the world.

Our Services

We are a partner you can count on

- Application advice:

take advantage of our decades of experience and find the right leveling technology for your needs. - Spare parts, repairs, maintenance and retrofitting:

we help you to keep your KOHLER levelers running economically and reliably.

- Contract leveling:

let us take on your part leveling tasks. Quick and with optimum leveling results. - Leveling trials:

We perform leveling trials with you in our leveling center. See the advantages of our hydraulic-free part leveling machines for yourself