Levelers

Spotlight on the efficiency and productivity of your sheet metal processing

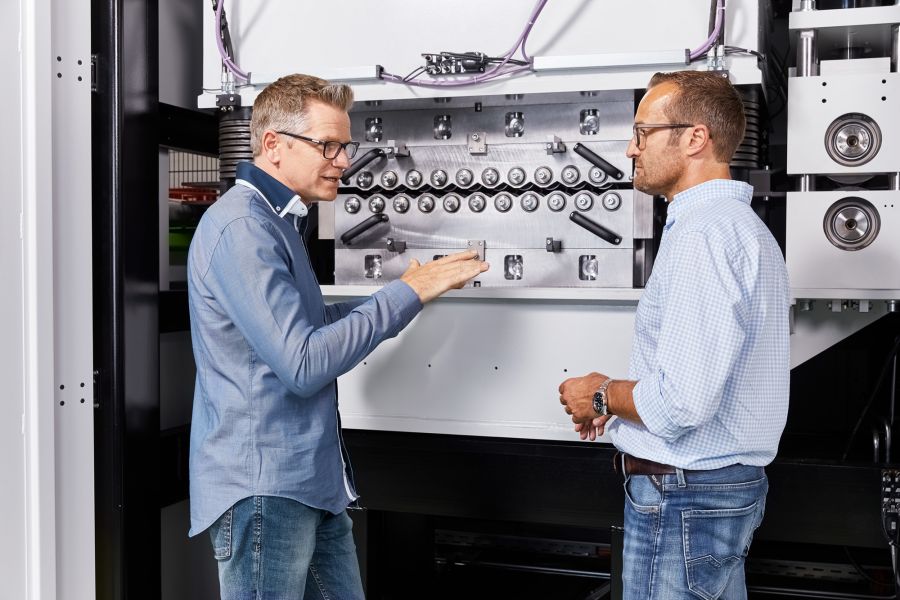

Leveling technology is KOHLER's core area of expertise. With almost six decades of experience, we supply reliable and precise levelers, feed leveling machines, and camber leveling units which ensure a high level of efficiency and productivity for your sheet metal processes. Our specialists provide detailed advice so you can invest in the right machine for your needs.

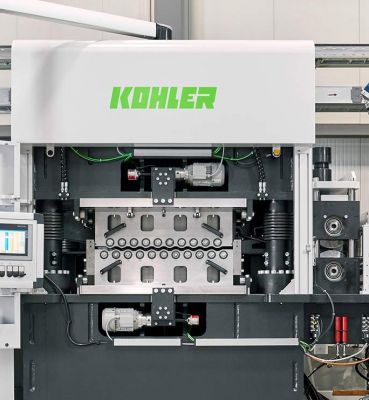

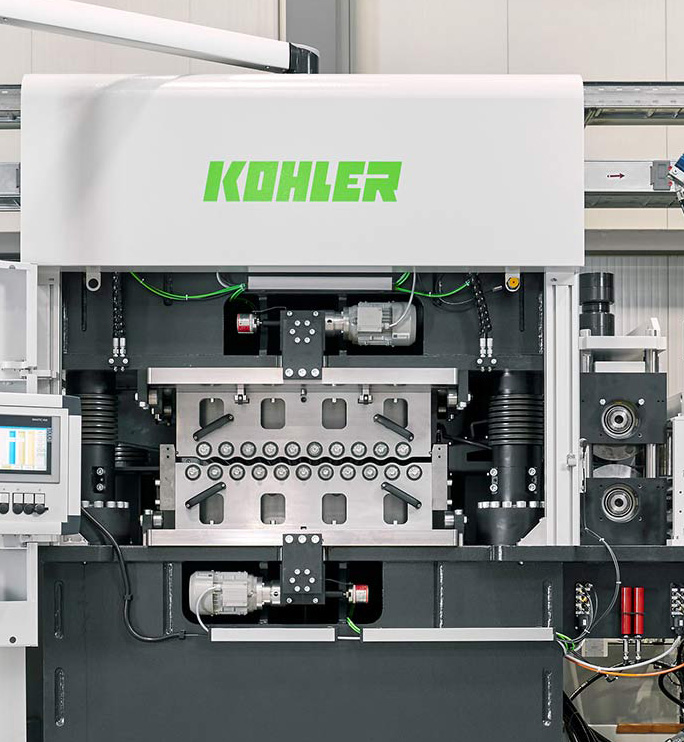

Precision leveling machine für the connector industry

KOHLER launches new compact precision leveling machine for manufacturing plugs, connectors, and electronic components

The KOHLER CPL leveling machine is tailored to the future needs of the "connector industry": As a space-saving precision leveler, it can be arranged above or following a standard horizontal decoiler. It levels coil material with a thickness of max. 2 mm and a width of max. 120 mm. The leveler has high rigidity and is equipped with nineteen leveling rollers, the diameter of which is precisely matched to the strip thickness. During leveling, it achieves a very high plasticizing degree. This allows reproducible precise leveling results to be met - even with low-quality coil material. On request, KOHLER can supply the precision leveler with a suitable machine control system.

Precision Leveling Machines

The heart of every strip leveling line

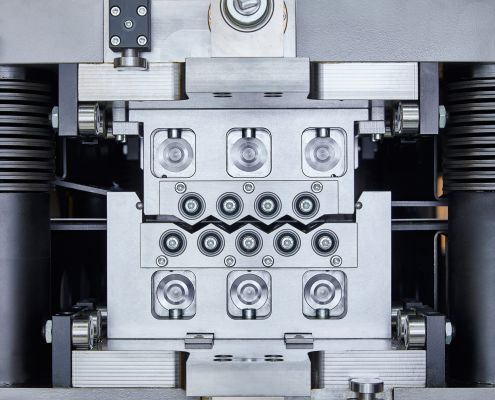

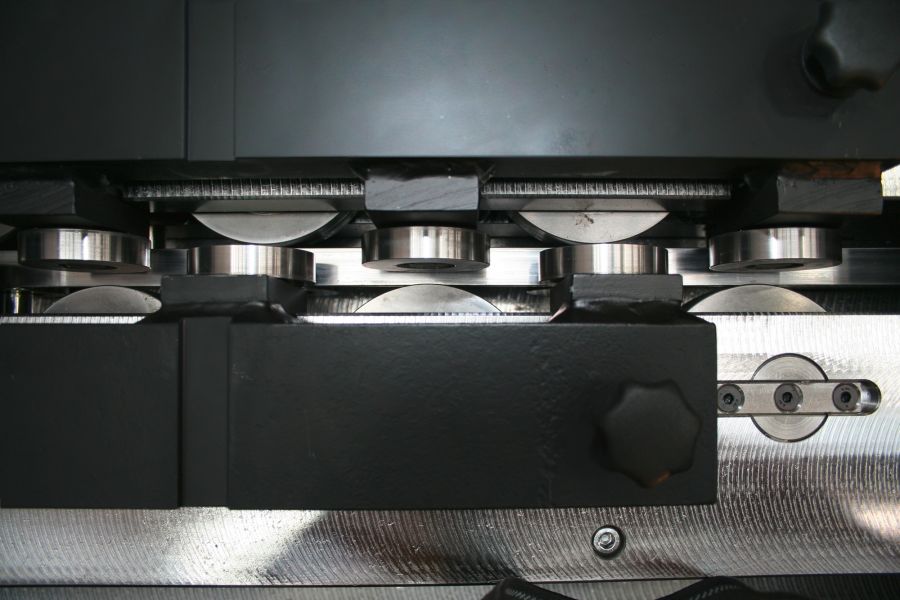

As the leader in leveling technology, KOHLER develops and produces precision leveling machines for strip leveling lines which deliver optimum leveling results over the long term. Depending on the equipment required, your KOHLER leveler may feature:

- 9/21 leveling rollers for ultimate leveling precision

- Hard chrome leveling rollers

- Intermediate rollers

- Roller bending for correcting edge and center waves

- Advanced cleaning and quick-change device

All of which ensures gentle processing, even of delicate materials.

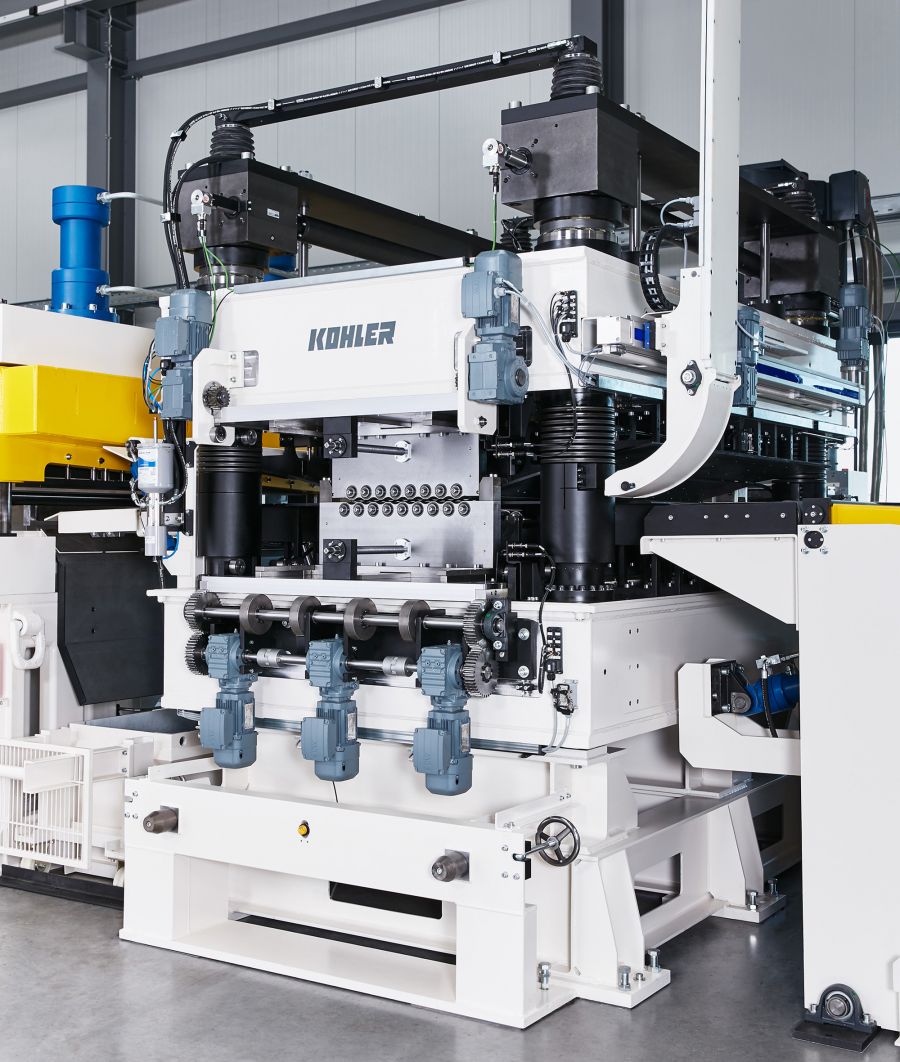

Highest end drive technology for strip leveling machines

Efficiency, sustainability and economy: This is the foundation KOHLER uses to drive the further development of its machines and lines forward.

So in the newest generation of precision leveling machines the usual distribution gears are no longer used to drive the levelling rollers. Instead, KOHLER uses an energy efficient drive concept with direct drives which works without cardan shafts. This reduces maintenance efforts significantly, as the absence of cardan shafts no longer requires an oil bath lubrication. And: the innovative direct drive of the leveling rollers increases the leveling range with material processing that goes easy on the surface at the same time. It is also used for the pinch rollers meaning that also here no cardan shafts are used for driving. The consequent implementation of the new drive concept lowers the energy consumption – saving cost in operation.

Feed Leveling Machine

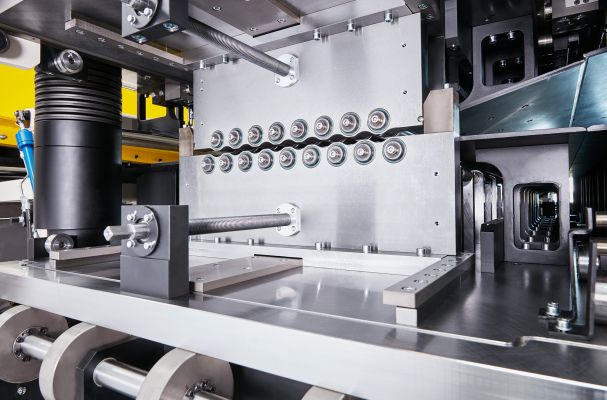

Precisely leveled – precisely timed

Feed leveling machines from KOHLER feed the strip with precision timing into the press or stamping machine – including in zig-zag operation if required. Feed leveling machines are ideal for compact strip leveling lines. As there is no loop, these require less space.

The compact feed leveling machine for the compact strip feeding line developed by KOHLER has generously sized supporting rollers which optimize the force flow and thus the output range. The direct drive of the leveling rollers increases the leveling area while consuming less energy. The top roller frame can be swiveled up by 35° thus facilitating access to the leveling rollers and making them quick and easy to clean, maintain, and remove.

KOHLER's feed leveling machines process sheets:

- With strip thicknesses of 0.5 to 8 mm

- With strip widths of 100 mm to 1,300 mm

- At up to 80 strokes per minute (product-dependent)

Camber Leveling Units

Reliably remove cambers in slit strips due to rolling errors

Camber leveling units from KOHLER reliably and precisely remove camber errors. As a pioneer in the field of camber leveling units, KOHLER can provide custom solutions at the highest technical level.

Other Components