Contract leveling for the future of e-mobility

Level, low-stress metal sheets for battery housing covers

voestalpine Automotive Components Dettingen GmbH & Co. KG, located in Dettingen an der Erms, Germany, is a prominent automotive supplier. As a specialized unit within the Metal Forming Division of voestalpine AG, the company partners globally to support the automotive industry in developing innovative lightweight construction solutions. voestalpine offers a comprehensive range of services, from materials and production technology to cost-efficient solutions, covering everything from blanks to ready-to-install components. With around 5,000 employees across 14 production sites worldwide, the voestalpine Automotive Components Cold Stamping & Assemblies Group is a key player in creating future-oriented lightweight solutions for mobility.

The company addresses several production challenges, including meeting tolerance requirements and industry standards, and implementing a zero-defect strategy crucial for its supplier ranking. voestalpine's machinery includes presses with capacities ranging from 100 to 3,000 metric tons, used for producing sheet metal parts. Their clientele includes major car and truck manufacturers globally. Production processes involve punching, forming coils, and laser cutting blanks, with 95% of production occurring on the coil line, followed by 3D forming. To achieve their zero-defect strategy, voestalpine collaborates with KOHLER Maschinenbau GmbH for leveling parts like battery housing covers.

Leveling the playing field for sustainable solutions

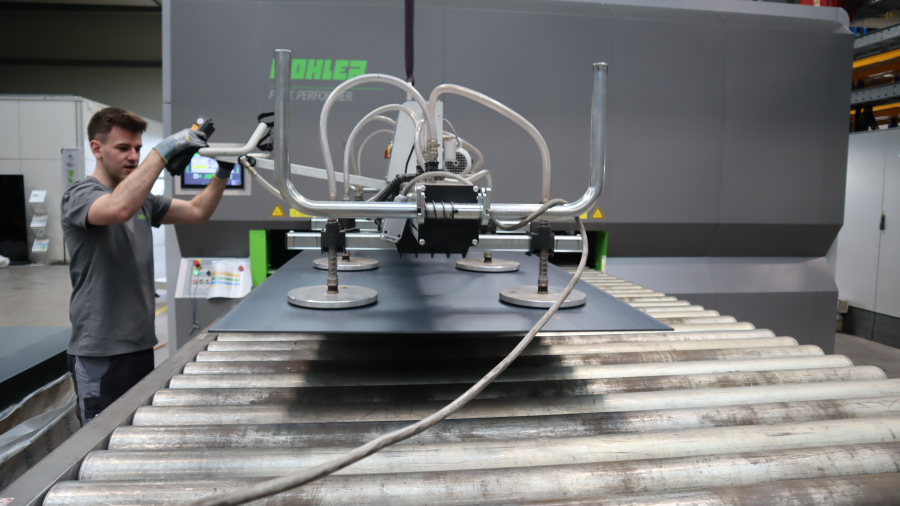

Collaborating with KOHLER has effectively resolved leveling issues, even for materials up to 13 mm thick. voestalpine aims to meet the highest quality standards and optimize downstream processes like lasering, drilling, and reworking surfaces and contours. S700 steel sheets, with a thickness of 6 mm, width of 950 mm, and length up to 2,560 mm, are leveled at KOHLER's contract leveling center. S700 is a high-strength, hot-rolled steel developed for cold forming, with a minimum yield strength of 700 MPa.

The requirements: levelness tolerance of up to 0.5 mm/m

voestalpine requires a leveling precision of 0.5 mm per meter, meaning S700 steel parts should only protrude 0.5 mm from a perfectly ground stone slab. “Without KOHLER, we couldn't achieve the flatness tolerance our customers need. We haven't had any more levelness issues since KOHLER started leveling the steel plates for our battery case covers. We're really happy with the results and have 250 metric tons of steel leveled every month. Saving time isn't our top focus – our main concern is getting our sheet metal level enough to achieve the requirements of our zero-defect strategy,” says Hans-Martin Reinhardt, head of the pilot series prototyping center at voestalpine Automotive Components Dettingen GmbH & Co. KG.

Hassle-free leveling without an in-house part leveling machine

Generally, all metals with a distinct yield point and an ultimate elongation of at least five percent can be optimally leveled. If these values haven't been determined, KOHLER Maschinenbau GmbH offers individual leveling trials at its center in Lahr, equipped with various Peak Performer part leveling machines. These machines can level sheet metal up to 2,500 mm wide and between 0.2 and 54 mm thick. For companies like voestalpine, where in-house leveling technology isn't feasible, KOHLER provides high-quality contract manufacturing with a broad range of part leveling machines, innovative features, and tailored services. Customers can rely on consistent leveling results, allowing them to focus on their core expertise, even when working with perforated sheets, thick sheets, or complex geometries.