30.09.2019

Industrie 4.0 - KOHLER machines support pioneering concepts

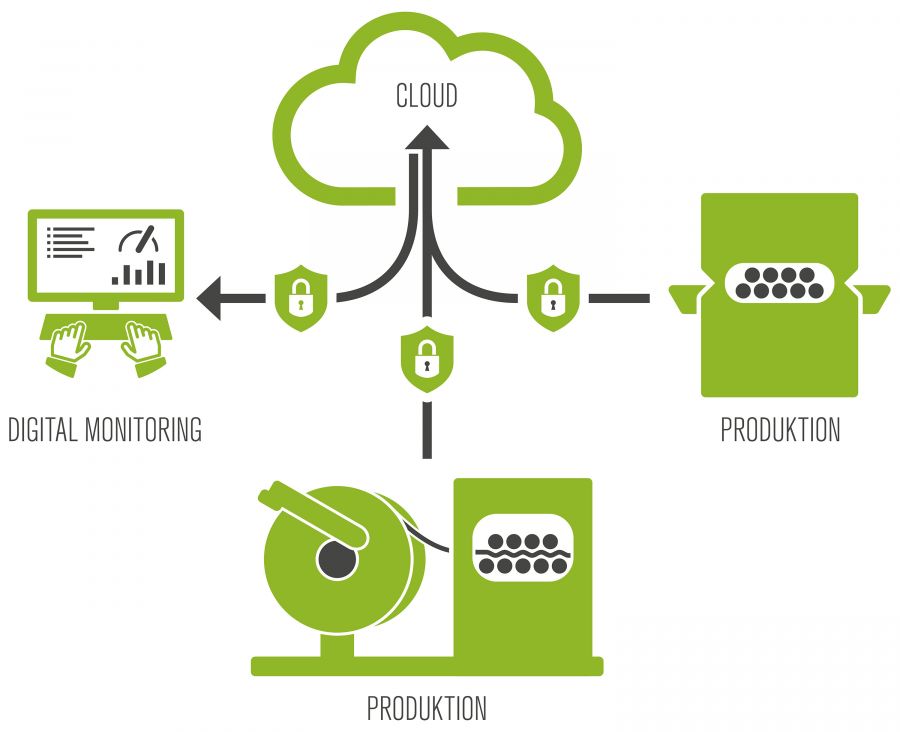

KOHLER is furthering the integration of cutting-edge technology into the products and processes of its customers in the shape of three new developments: The OPC UA interface provides the basis for the seamless networking of all machines which are involved in the production process; the digital maintenance module for strip leveling lines and part leveling machines optimizes machine maintenance; while the newly developed dashboard makes digital monitoring possible.

KOHLER is therefore meeting the demands of machine operators for forward-looking Industry 4.0 communication by providing structured machine data for the efficient monitoring and optimization of production processes. The aim is to easily integrate machines into existing lines and to reduce the complexity that leads to significant costs in terms of time and labor during the commissioning and conversion of entire lines and systems. Put simply, efficient production lines are the ultimate goal.

Predictive maintenance: The digital maintenance module

The maintenance module helps to ensure that maintenance work is planned in advance and completed in good time. When developing the maintenance module, easy and intuitive operation was a top priority for Dr. Markus Blust and his team. The necessary maintenance work is shown clearly on the display screen and KOHLER has designed the module to be very flexible, so that it can be adjusted to suit the customer's needs at any time. The entire current product range of strip leveling lines and part leveling machines has been upgraded with the PLC-supported maintenance module as standard equipment.

„We have developed the maintenance module in order to help our customers with two tasks. Firstly, the module notifies the customer automatically of any pending maintenance; and secondly, it records whether the maintenance work has been carried out.“

Dr. Markus Blust, Head of Engineering and Design

Plug & work: OPC UA networking

The foundation and key challenge for an easy and seamless interconnection of machines and other systems (e.g., ERP, cloud) is the platform-independent, interoperable, and manufacturer-independent exchange of data. This digital networking can be achieved with the standard OPC UA. All machines and lines from KOHLER can be easily integrated into existing system environments.

Condition monitoring: Overview

The information provided by machines does not usually have a uniform structure. The KOHLER dashboard allows machine and line data from various systems to be depicted in a clear and well-defined format. OPC UA also forms the basis for monitoring functions (data analytics, condition monitoring). The user has access to a variety of standardized information on the basis of current data, which not only simplifies machine maintenance, setup and capacity utilization, but also increases the overall effectiveness of the asset.

KOHLER and Industrie 4.0

For KOHLER, Industry 4.0 is not an abstract concept for the future. The company has developed solutions with which information and internet technology can be integrated into its products and consequently the processes of its customers. The communication between man and machine already exists at KOHLER in concrete concepts and developments.